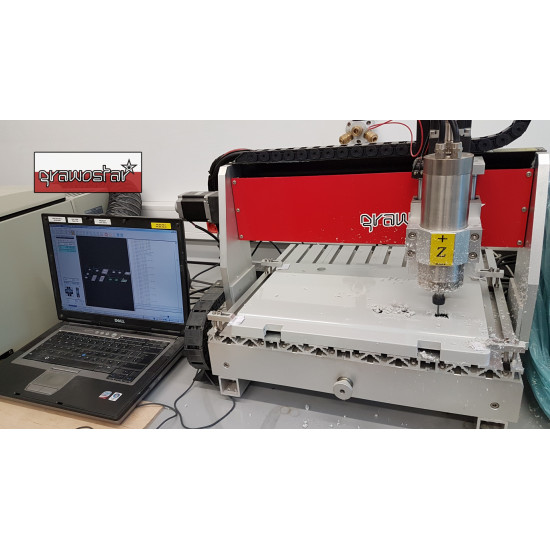

Grawostar Nemo Pro USB WARP

Grawostar Nemo Pro

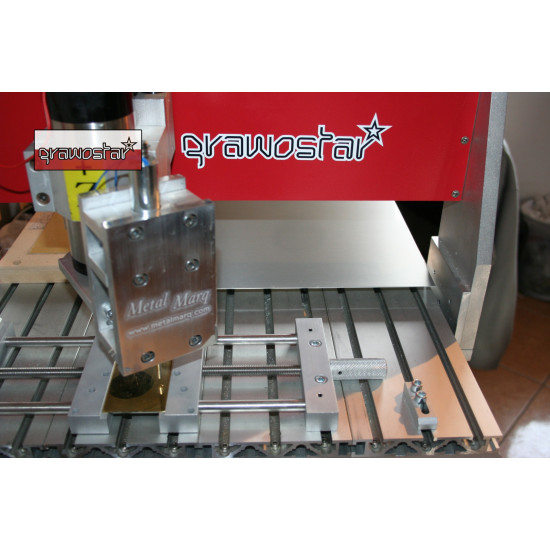

Grawostar Nemo Pro USB WARP – mini grawerka, frezarka, znakowarka z możliwością metalmarq’owania. Model Nemo Pro USB WARP jest najmniejszą grawerko-frezarką w ofercie maszyn TBH Polska.

Nemo Pro USB WARP jest modyfikacją modelu Nemo Pro. W Nemo Pro USB WARP panel sterujący został wyeliminowany a poprzez zastosowanie nowej elektroniki wszystkie prace sterujace urządzeniem można wykonywać na komputerze do którego jest podłączona grawerka.

Modele Nemo Pro USB WARP produkowane są przede wszystkim dla nowo powstałych zakładów grawerskich, sklepów z pamiątkami, zakładów przemysłowych, zakładów energetycznych, warsztatów szkolnych, odbiorców indywidualnych oraz dla firm zajmujących się grawerstwem 3D.

Zastosowanie

Grawostary z uwagi na ich wszechstronność i odpowiednio dopasowaną moc wrzeciona nadają się do produkcji tablic znamionowych, grawerowania zegarków, zawieszek, nieśmiertelników, okazjonalnych opakowań, tabliczek, breloków, kluczy, odlewów z wosku, matryc, patryc, noży, sztućców, laminatów, części samochodowych, pleksi, akrylu, drewna, telefonów, gadżetów reklamowych, produktów okazjonalnych, medali.

Przez swoją sztywność urządzenia Grawostar z powodzeniem wykorzystywane są do do frezowania form wtryskowych, szyldów reklamowych z pleksi, plastiku, drewna, tablic informacyjnych z aluminium, mosiądzu i wielu innych artykułów codziennego użytku.

Wszechstronność i konfiguracja

Urządzenia marki Grawostar konstruowane są tak, by maksymalnie zwiększyć ich funkcjonalność. Efektem naszej pracy jest rosnące zadowolenie naszych klientów wynikające ze stałej przewagi oferowanych usług nad konkurencją. Dzięki przemyślanej budowie większość oferowanych urządzeń możemy rozbudować o:

- Przystawkę obrotową - przystawka służy do grawerowania po okręgu, przedmiotów okrągłych, obłych (przy zastosowaniu MetalMarq) *

- Przystawkę grawerską MetalMarq wraz z uchwytem (opracowaną w firmie Quedex)

- Uchwyt jubilerski do grawerowania obrączek wewnątrz i na zewnątrz*

- Przystawkę MetalMarq Ring do grawerowania wewnątrz obrączek wraz z uchwytem*

- Przystawkę Glaver do grawerowania przedmiotów ze szkła

- Stół z podsysem

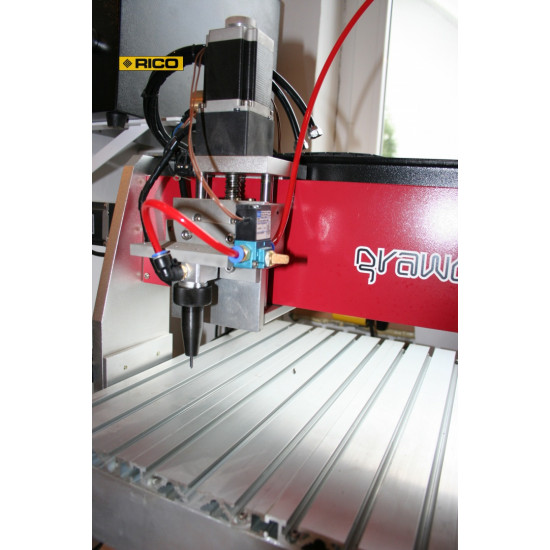

- System chłodzenia narzędzia i materiału obrabianego

- System chłodzenia wrzeciona typu "comfort", ‐ Automatyczną zmianę narzędzia (opcja dostępna tylko w większych modelach urządzeń)

- Profesjonalne systemy odciągu zanieczyszczeń firmy TBH

Adaptacja systemu dla klienta

Możliwości rozbudowy grawerko‐frezarek Grawostar są zależne od konfiguracji poszczególnego modelu. W przypadku chęci grawerowania produktów po okręgu (dookoła osi A) zapraszamy do kontaktu. Posiadamy w swojej ofercie wiele modeli, w różnych konfiguracjach dostosowanych do potrzeb naszych klientów Dodatkowo na etapie produkcji możemy:

- Zaadoptować pole robocze XY na zamówienie klienta

- Zwiększyć/zmniejszyć posuw w osi Z

- Zainstalować wannę zbierającą olej chłodzący narzędzie i materiał

- Zainstalować obudowę ochronną. W zestawie do urządzeń może być dołączone CD z profesjonalnym oprogramowaniem grawerskim (Artcam Express, Insignia lub Pro, Cut 2D, Cut 3D, Type3, Vectric Vcarve) - zależnie od dodatkowo zamówionej opcji

Kontroler CNC WARP - nowe możliwości

W każdym przypadku dołączony jest kontroler zewnętrzny pozwalający sterować urządzeniem bez użycia komputera, zestaw uchwytów, przewód zasilający. Grawostar Nemo Pro USB WARP jest najmniejszym oferowanym urządzeniem wyposażonym w śruby kulowe, falownik, wrzeciono o niespotykanej mocy i posuwem realizowanym na doskonałych silnikach krokowych.

Najczęściej zamawianym dodatkiem do tego urządzenia jest przystawka opracowana i wyprodukowana w firmie ‐ Quedex ‐ MetalMarq (pseudo 3D grawerowanie w metalu na płasko).

Przystawka rysuje po powierzchni i może idealnie wygrawerować różnego rodzaju tabliczki znamionowe jako alternatywa dla standardowego grawerowania materiału ‐ skrawaniem. Dodatkowo przystawka posiada tolerancję nierówność niektórych materiałów do 10mm ! UWAGA: Do wszystkich modeli Grawostarów szkolenie z instalacji oraz obsługi oprogramowania grawerskiego w cenie urządzenia!

Dane techniczne

- Zasilanie: 230V / 50 Hz (jednofazowe)

- Moc maksymalna zestawu: 1500W

- Obszar roboczy: ( X x Y x Z ) 380 x 300 x 55mm

- Prześwit pod bramą: 90mm

- Prędkość posuwu ( X / Y ): 0-4000 mm/min (max. 5000 mm/min)

- Wrzeciono: Zaawansowane sterowane inwerterem (trójfazowe)

- Chłodzenie wrzeciona: cieczą (opcjonalnie powietrzem)

- Moc silnika wrzeciona: 800W

- Prędkość obrotów wrzeciona: 0-24000 obr/min

- System posuwu: Śruby kulowe

- Rodzaj silnika posuwu ( X / Y / Z ): Krokowy

- Czujnik powierzchni Z: Tak

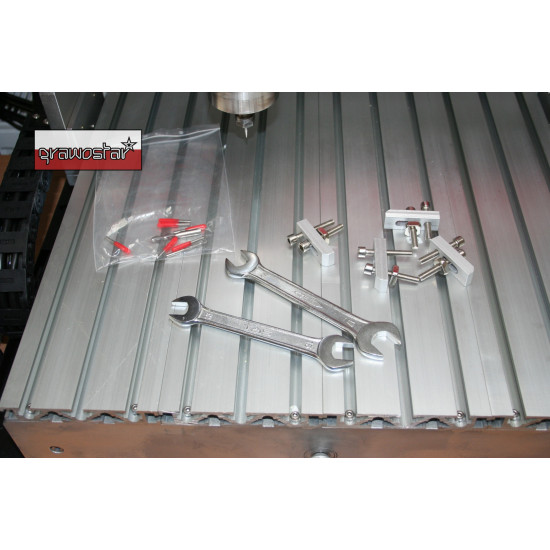

- Stół teowy: Tak

- Klucze w zestawie: Tak

- Uchwyty w zestawie: Tak

- Frezy w zestawie: 5 szt.

- Uchwyt narzędzia w zestawie: Φ3.175 (standard ER 11)

- Rozdzielczość: 0.01mm

- Współpraca z PC USB: Tak

- Kompatybilność z wybranymi postprocesorami: Tak

- Wizualizacja ścieżki narzędzia i pozycji w czasie rzeczywistym: Tak

- Możliwość podłączenia skanera 3D: Tak

- Możliwość podłączenia kamery USB: Tak

- Możliwość sterowania 4-tą osią z poziomu kontrolera: Tak

- Zaawansowane funkcje CNC: Tak

- Wymiar ( X x Y x Z ): 650 x 550 x 450mm

- Waga: 45 kg

Filmy z pracy urządzenia